Backcutting is the most economical and effective method to descale waste stacks

Backcutting / Descaling

DRS Co have developed the most efficient way to de-scale pipes. Back-cut the scale to metal. That means removing the cause of the problem from top to bottom of the stack. With no compromise. A service that should not be needed for another 20 years.Backcutting is the most economical and effective method to descale waste stacks. Common complaint from tenants are: They are experiencing bad smells emanating from either the kitchin sinks or the bathroom wastes; back surges of dirty water into the kitchen sink or bath; or flood due to back surges.Backcutting is a best value service.

What is backcutting?

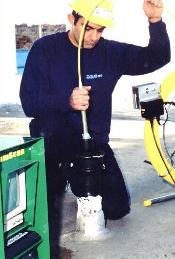

This 100mm cast iron pipe has been prepared to show the cutters in relation to the scale and the basic principal of how the backcutting process works and why it is a major step forward in dealing with this sort of problem. The cable is passed from the top of the pipe from some convenient point. Either the vent with a flat roof building or an access door from the top flat or even in some cases via the top floor waste junction. The cable is passed from top to bottom till it emerges in to the back-inlet gully or drain. The cutters are then placed on the end. The water is introduced in to the pipe and a flow of water is established. Two men are in constant radio contact, the reason is to ensure that none of the flats involved on that stack are being flooded with the water we need to wash away the cuttings.

Following confirmation that there is a water flow the men who work the machine then slowly bring the cutters back in to the pipe. So as the cutters rotate the water washes away the debris to leave the pipe cleared back to bare metal. In some cases we might need to introduce smaller cutters then larger ones till the work is done.

The cable is rotated to cut away the scale till it reaches the top then a second cut is made down untill the cutters can be removed. The main principal of this method is that the cutters will not go back untill they have cut the scale back to the size of the cutter. This proves the pipe all the way from top to bottom leaving it clear for another 20 years or so.

The benefits of Backcutting

- Is cost effective as one back cut process usually services up to 6 flats at a time.

- Once serviced that stack should last another 20 years before it needs another.

- The service can be applied to a single emergency stack problem or the servicing of stacks in a regeneration program.

- No jetting is required, so the problem of flooding does not arise from high-pressure water.

- The tenants are not inconvenienced while the work is in progress. And we are quick and efficient if we are forced to carry out the work from the top flat.

- Back cutting can be adapted to de-scale any height of building. And deliver a pipe as good as new.

- The pipe can be in constant normal use while the process is under way.